Workplace safety is paramount, especially in environments where employees handle hazardous materials. One essential safety measure is installing emergency shower and eyewash stations to provide immediate decontamination in case of exposure to harmful substances.

But where do you think you should place your emergency shower and eyewash station?

Proper placement of these stations is critical to ensure they are accessible and effective. This guide outlines where you should put your emergency shower and eyewash station and offers practical advice based on Australian safety standards.

Why is Placement Important for Emergency Showers and Eyewash Stations?

An emergency shower and eyewash station is designed to protect workers by providing quick access to decontamination facilities in the event of chemical splashes, burns, or other injuries. Improper placement can delay response time, increasing the risk of severe injury. Ensuring these stations are strategically located can make a significant difference in workplace safety.

Emergency Shower and Eyewash Station Requirements

In Australia, the placement and functionality of emergency shower and eyewash stations must comply with AS 4775-2007, the standard governing the design, performance, and installation of these safety devices. Key requirements include:

- Proximity to Hazards: Stations should be located within 10 seconds (approximately 15-20 metres) of potential hazards.

- Unobstructed Access: The path to the station must be free of obstacles, allowing immediate access in case of an emergency.

- Adequate Water Flow: The shower must deliver a minimum of 76 litres per minute, and eyewash stations must provide a flow of 1.5 litres per minute for at least 15 minutes.

- Consistent Water Temperature: Tepid water (16-38°C) is required to prevent further harm to the injured individual.

- Signage and Lighting: Stations must be well-lit and clearly marked with visible signage to ensure workers can locate them easily.

Where Should You Place Your Emergency Shower and Eyewash Station?

1. Close to Hazardous Areas

The station should be easily accessible from areas where hazardous materials are used or stored. Common locations include:

- Chemical Storage Rooms: Ideal for managing spills or accidental exposure during handling.

- Laboratories: Essential for quick decontamination following chemical splashes.

- Manufacturing Floors: Where exposure to corrosive substances, solvents, or powders is possible.

2. In High-Risk Zones

Identify areas where accidents are most likely to occur. Risk assessments can help pinpoint these zones. Examples include:

- Mixing or Dispensing Areas: Locations where workers interact directly with hazardous chemicals.

- Battery Charging Stations: Risk of exposure to acid spills or other corrosive substances.

- Spray Paint Booths: Potential for inhalation or splashes of harmful chemicals.

3. Away from Potential Hazards

While the station should be near hazardous areas, ensure it’s not directly within the hazard zone. For example:

- Avoid Placing Stations Near Electrical Panels: To reduce the risk of electrocution.

- Steer Clear of Heavy Traffic Areas: Prevent accidental obstruction or damage to the equipment.

Emergency Shower and Eyewash Station Checklist for Optimal Placement

There’s actually no specific eyewash station checklist for where to place your eyewash stations. But our professionals at Ecospill would love to help you out with a crafted checklist you can use.

Here’s a practical checklist to ensure your station is appropriately placed and fully functional:

- Accessibility: Can the station be reached within 10 seconds without barriers or obstructions?

- Visibility: Is the station clearly marked with signage and positioned in a well-lit area?

- Water Supply: Does it meet the emergency shower and eyewash station requirements for water flow and temperature?

- Maintenance: Is the station inspected and tested regularly to ensure it’s operational?

- Employee Training: Have employees been trained on how to locate and use the station effectively?

Using an emergency shower and eyewash station checklist helps businesses maintain compliance and ensure employee safety.

Emergency Eyewash Station and Safety Shower Guidelines

1. Compliance with Australian Standards

Ensure the station complies with AS 4775-2007 standards, which cover:

- Performance requirements for effective decontamination.

- Installation standards for visibility and accessibility.

- Maintenance guidelines for consistent functionality.

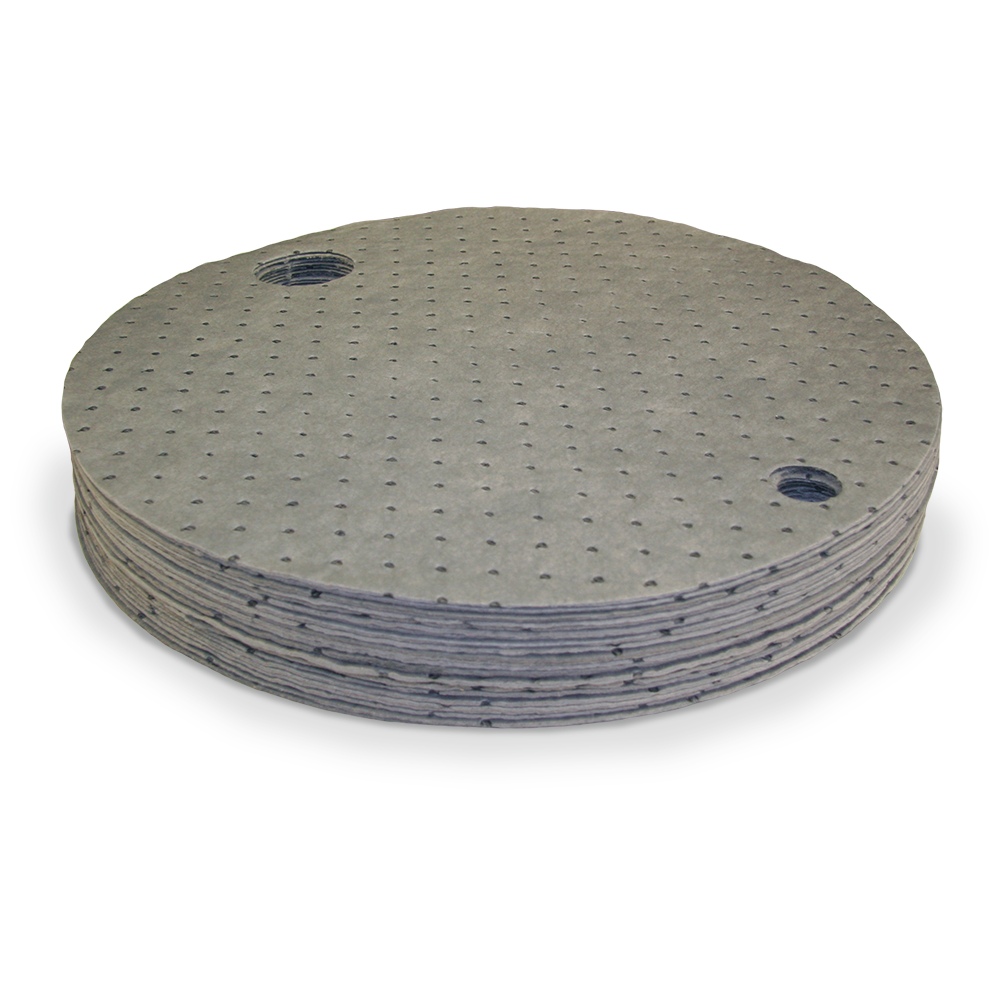

2. Integrating with Spill Kits

Incorporate your emergency shower and eyewash station into your overall spill response plan. Pairing it with a spill kit ensures a comprehensive approach to managing workplace hazards.

3. Customised Solutions

No two workplaces are the same. Consult with safety professionals to design a setup tailored to your specific needs, whether it involves multiple stations or specialised equipment for unique risks.

Maintaining Your Emergency Shower and Eyewash Station

Regular maintenance is crucial for ensuring your station remains operational. Key steps include:

- Weekly Activation Tests: Flush the system weekly to verify water flow and remove stagnant water.

- Annual Inspections: Conduct comprehensive evaluations to ensure compliance with an emergency eyewash station and safety shower guidelines.

- Documentation: Keep records of inspections and tests to demonstrate compliance with workplace health and safety standards.

Be Prepared at All Times

The correct placement of your emergency shower and eyewash station can make all the difference in a workplace emergency. Aside from having an emergency shower and eyewash station checklist, you should also make sure you abide by Australian standards to avoid penalties.

Looking for emergency shower and eyewash stations in the land down under? Ecospill has what you need when you need it! Our team offers expert advice and ongoing support to help businesses ensure a safe working environment.

Explore our website to see a range of emergency safety products and ensure your workplace is fully equipped and compliant.