How to Choose the Right Oil Absorbent Pads for Your Needs

Picture this: you’re a business owner in the manufacturing industry, and one of your machines springs a leak.

Before you know it, you’ve got a significant oil spill on your hands. Not only do you have to deal with the cleanup costs, but you’re also worried about the environmental impact of the spill. This is where having the right oil absorbent pads can make all the difference. With so many options available, it can be challenging to know which ones to choose.

In this blog post, we’ll guide you through the process of selecting the best oil absorbent pads for your specific needs. From understanding the benefits of these pads to knowing what to look for when making a purchase, we’ve got you covered. So, let’s get started and make sure you’re prepared for any oil spill or leak that may come your way.

What are Oil Absorbent Pads?

Under the Work Health and Safety Act 2011, Australian businesses are responsible for preventing and preparing for workplace oil spills, with due diligence being a key component. This involves providing appropriate equipment and training to reduce the likelihood of spills and minimise their impact. Failure to comply with these regulations can result in legal action if an incident results in injury, property damage, or environmental harm.

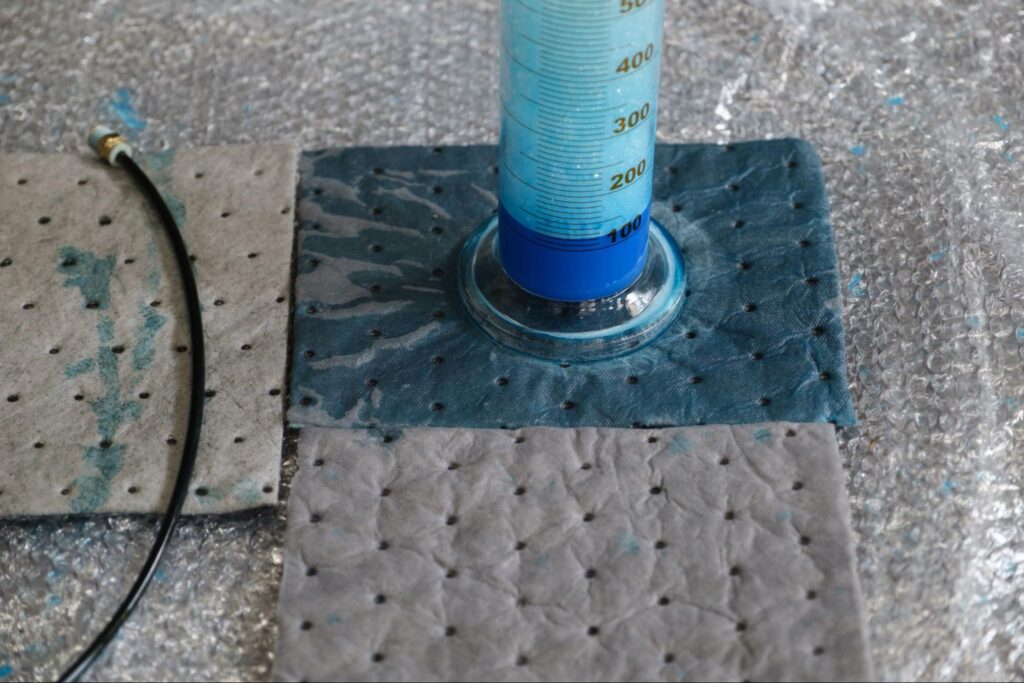

Oil absorbent pads are specialised pads designed to absorb and contain oil spills and leaks in industries where machinery, vehicles, or equipment operate with oil, such as manufacturing, transportation, and construction. These pads play a crucial role in preventing environmental damage and reducing equipment downtime.

These pads are particularly useful when working with heavy machinery, where spills and leaks are common. By placing the pads under the machinery or equipment, they catch drips and leaks before they have a chance to make their way onto the ground. This creates a protective barrier that keeps your work area clean and prevents spills from causing damage.

Overall, oil absorbent pads are an essential tool for any industry that works with oil or other hazardous liquids. By providing a quick and easy solution to contain spills, they help keep the work environment clean and prevent any spills from causing damage.

Types of Oil-Only Absorbent Pads

Oil-only absorbent pads come in various forms, each with its unique features and benefits. Understanding the different types of oil absorbent pads is crucial in choosing the right one for your needs. Here are some of the most common types of oil-only absorbent pads:

- Bonded oil absorbent pads: These are pads made from a single layer of fine fibres that are bonded together using heat and pressure. They have excellent absorbency and strength, making them ideal for cleaning up oil spills in high-traffic areas.

- Meltblown oil absorbent pads: These pads are made by extruding melted polypropylene through a die, creating a non-woven fabric with excellent absorbency. Meltblown pads are cost-effective and suitable for general-purpose use.

- Laminated oil absorbent pads: These are pads made by bonding two or more layers of meltblown polypropylene together. They have a higher absorption capacity than single-layer pads and are ideal for cleaning up larger spills.

- Fine fibre oil absorbent pads: These pads are made from a blend of fine fibres that have been hydrophobic-treated to repel water and attract oil. They have a high absorbency rate, making them ideal for cleaning up small spills in tight spaces.

- Track mats: These are heavy-duty, oil-only absorbent pads designed to be used as a barrier under heavy machinery or vehicles. They help prevent oil spills and leaks from reaching the ground, reducing the risk of damage to the environment and equipment.

When choosing the oil-only absorbent pad, consider factors such as absorbency, durability, and cost-effectiveness. The type of pad you select will depend on the industry you’re in, the type of equipment you’re working with, and the potential risk of oil spills and leaks. To explore other types of oil sorbents and their applications, click here.

Benefits of Oil-Only Absorbent Pads

Below are some of the many benefits of oil-only absorbent pads:

1. Highly absorbent

Oil absorbent pads are specifically designed to effectively absorb oil spills and leaks, making them a highly efficient solution for preventing contamination and reducing environmental hazards.

2. Good tear strength

Oil absorbent pads are durable and have good tear strength, which makes them easy to use and reduces the risk of the pad tearing apart during cleanup.

3. Environmental friendly & safe

Oil absorbent pads are designed to help keep the work environment clean and prevent contamination, making them an ideal choice for use in various industries. In addition, by quickly containing and absorbing oil spills and leaks, these pads help reduce the risk of slips, falls, and other workplace accidents that can occur when oil is left to accumulate on floors or equipment.

4. Easy to use

Oil absorbent pads are simple to use and require no special training or equipment. They can be easily placed under machinery or vehicles to prevent oil spills and leaks from spreading and contaminating the surrounding area.

5. Cost-effective

Oil absorbent pads are a cost-effective solution for preventing oil spills and leaks. They are less expensive than other types of cleanup materials and can save businesses money on cleanup costs.

6. Suitable for Biofarms

Oil absorbent pads can be used in biofarms to prevent oil contamination in soil and water, which is important for maintaining the health and safety of crops and animals.

How to Choose the Right Oil Absorbent Pads for Your Needs

When selecting oil absorbent pads, it’s crucial to take several factors into account to ensure that you choose the most suitable option. Below are three essential considerations to keep in mind:

1. Choose a mat with good materials

Look for pads made from high-quality materials such as meltblown polypropylene, which provides excellent absorption and durability. The Ecospill Track Mat, for example, is made out of high-quality materials, including a top layer of black UV stabilised needle punch and a second layer of high-strength white meltblown polypropylene. The base layer is made of heavy-duty plastic, ensuring durability and longevity.

2. Opt for heavy-weight mat materials

When choosing oil absorbent pads, the weight of the pads is a key factor to consider. Heavy-weight pads are more absorbent and can handle larger spills without tearing or falling apart. This ensures that the absorbed material won’t stain the floor surface under the pad, giving you the ultimate confidence in its ability to contain spills.

3. Consider your matting location

Consider where you’ll be using the pads and choose a size and shape that will fit the space properly. If you need to use the pads outdoors, make sure they are designed to withstand the elements. For example, if the pads will be placed under vehicles and machinery to absorb oil spills, make sure they are the appropriate size and shape for the equipment and can handle outdoor conditions.

Don’t Let Oil Spills Slow You Down: Choose the Right Absorbent Pads Today!

Oil spills can be a hazard to both the environment and workers. Therefore, it’s important to choose the right oil absorbent pads to prevent spills and keep your workplace safe. At Ecospill, we offer a wide range of premium-quality oil absorbents to help workplaces remain safe and meet their environmental obligations. Our Ecospill Track Mats are a heavy-duty, oil-only absorbent barrier product specially designed for placing under vehicles and machinery to contain oil, ensuring that any spills or leaks are safely absorbed.

So why wait? Choose the right absorbent pads today and stay ahead of any spills or leaks that might slow you down.