Choosing the Right Drum Mat Material for Chemical Compatibility

If you’re handling various chemicals and liquids that may be hazardous to human touch and our environment, you might have known that it is of utmost importance to know how to handle and which materials to use for these chemicals.

Because of that, it’s important that you invest in a proper chemical storage in your business to avoid any type of harm that might happen. And when you already have drum containers, you might also want to have drum mats.

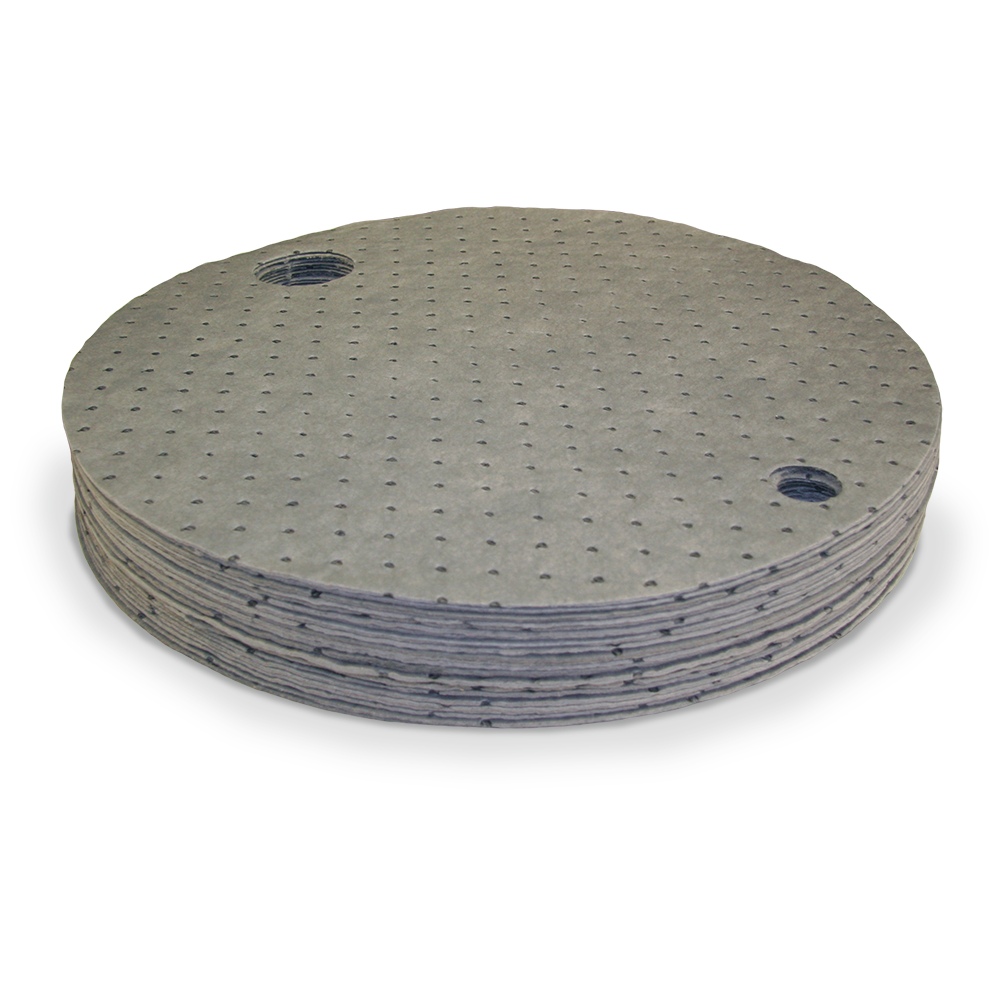

Drum mats have the capability to help you prevent and handle spills, leaks and contaminations when storing your chemicals in drum containers. What you might not know is that these mats come in different matierials, and choosing which kind of drum mat is not as simple as it seems.

See which drum mat material is the right one for your business!!

The Importance of Chemical Compatibility in Drum Mats

When handling hazardous chemicals, choosing a mat made from the right material lowers risks by providing a safe barrier against spills.

Using a mat that doesn’t work well with certain chemicals can shorten its lifespan, reduce its effectiveness, or even create unsafe conditions. Moreover, it can be a complete waste of resources if you choose a wrong drum mat. That’s why it’s essential to understand the strengths and weaknesses of each material and pick a mat that can be used for a long time and a great value for your buck!

Understanding Chemical Compatibility

Chemical compatibility largely depends on the properties of the chemicals involved. Consider factors such as:

Acidity or Alkalinity: Chemicals with high acidity or alkalinity may degrade certain materials quickly.

Volatility: Volatile chemicals can penetrate or weaken some mat materials.

Viscosity and Composition: Thicker or oily chemicals may require specific absorption capabilities that not all mats can provide.

Consult the chemical’s Safety Data Sheet (SDS) for compatibility guidelines and ensure your choice aligns with both the substance type and potential exposure duration.

Types of Drum Mat Materials and Their Compatibility

Various drum mat materials are designed to handle specific substances. Here’s an in-depth look at common mat materials and their best applications:

Polyethylene (PE)

Polyethylene is one of the most common materials for drum mats because of its resilience and chemical resistance. Typically durable, PE is suitable for a wide range of chemicals, particularly:

Oils and Fuels: PE mats resist oils and fuel chemicals well, making them ideal for automotive or industrial environments.

Mild Acids and Alkalis: While not suited for highly corrosive substances, polyethylene can handle mild acids and alkalis without significant degradation.

PE’s robustness also makes it a practical choice for locations requiring frequent replacement, as it balances durability and cost-effectiveness.

Polypropylene (PP)

Polypropylene is another highly absorbent and versatile option, especially for hydrocarbon-based chemicals. Known for its efficiency in containing oils, PP mats are best for:

Hydrocarbons: Effective for oil spills, PP mats quickly absorb petroleum and similar products, making them popular in industrial and marine settings.

Non-Acidic Solutions: Polypropylene is more vulnerable to strong acids but performs well with less aggressive substances.

Because of its rapid absorption rate, PP mats are ideal in areas where spills are frequent, ensuring fast containment and easy cleanup.

Rubber-Based Mats

Rubber-based mats are valued for their durability and resistance to certain corrosive chemicals, especially:

Acidic Solutions: Rubber is highly resistant to acidic substances, making it suitable for laboratories and facilities that frequently handle acids.

High-Traffic Areas: Rubber’s tough structure withstands wear and tear, making it ideal for locations with heavy foot or equipment traffic.

These mats are often less absorbent than polypropylene or polyethylene, so they’re more appropriate for containment than direct spill absorption.

Rubber mats may also be more expensive, but their durability often justifies the investment in acidic environments.

Factors to Consider When Choosing Drum Mats

Choosing the right mat material goes beyond chemical compatibility. Consider the following aspects for optimal performance and safety:

Absorption Capabilities

Some drum mats prioritise absorption, ideal for quick spill containment, while others focus on resistance to degradation. For instance:

High Absorption: PP mats absorb quickly and are better suited for environments where spills are frequent and need quick containment.

Durability Over Absorption: Rubber mats prioritise durability over absorption, best suited for containment applications with corrosive materials.

Environmental Conditions

Temperature and humidity also influence mat performance. For example:

Temperature Sensitivity: PE and PP are generally stable but may become less effective under extreme temperatures.

Moisture Resistance: In humid environments, mats need to resist moisture to prevent degradation and mould.

Cost and Maintenance

Assessing cost-effectiveness is essential, particularly if mat replacement is frequent:

Budget-Friendly Options: PE mats are often affordable and practical for general use.

Long-Term Investment: Rubber mats may have a higher upfront cost but require less frequent replacement, making them cost-effective over time in specialised applications.

You can also check out some tips on how to best use your drum mats to maximise their functions.

Find the Right Drum Mat Top

Selecting the right drum mat material means thinking carefully about the chemicals you’re handling and the conditions in your workspace. Materials like polyethylene, polypropylene, and rubber offer choices that balance absorption, resistance, and durability.

If you’re looking to find the right drum mat top and ensure that everything you use is compatible with your chemicals, Ecospill’s various drum tops are the way to go. Designed to keep your chemicals contained and safe, these tops have the materials that match your drums perfectly, giving you the protection you need.

Visit our website to see all the products we have to offer to help you in your chemical spill management and storage.